More Flexible, more Efficient, Safer: MAN eBuses with New Batteries from In-house Production from 2025 Onwards

MAN is continuously developing the fully electric city bus in collaboration with its customers. The 2025 model year will see the launch of the next major product update for the Lion’s City E. The highlight is the new battery generation with the latest lithium-ion battery technology (NMC) from MAN’s own production facility in Nuremberg, which is currently ramping up to an initial capacity of 50 000 packs per year. Operators, drivers and passengers will benefit from even greater efficiency, safety and flexibility. The vehicle with the new MAN BatteryPack celebrated its premiere at the UITP Summit in Hamburg. Series production is scheduled to start in the fourth quarter of 2025. “In the 2024 model year, we have upgraded our eBus with many new and smart features,” says Robert Katzer, Head of Sales & Product Bus at MAN Truck & Bus, adding: “Thanks to the latest update, the Lion's City E is now taking another huge leap forward.”

Electrifying: More than 2 500 MAN e-buses in service in Europe MAN pursues a clear zero-emission strategy and has already been successfully operating the Lion’s City E family for urban and interurban transport for six years. Since its market launch in 2019, the company has sold more than 2 500 electric buses in Europe, which have covered over 100 million kilometres in everyday use without emissions to date. In the first quarter of 2025 alone, sales totalled 283 eBuses. This corresponds to more than 50 percent of the city buses sold by MAN in Europe. This success is largely based on the wide range of emission-free buses, which is being continuously expanded. The MAN electric bus portfolio includes manoeuvrable 10-metre vehicles, classic 12-metre solo buses and 18-metre articulated buses for maximum capacity requirements, as well as electric lowentry vehicles for interurban transport. With the Lion's Chassis E, MAN can also serve markets outside Europe with environmentally friendly mobility solutions.

New batteries from the MAN factory in Nuremberg In addition to the extensive portfolio, another key factor in the success of the Lion’s City E is its continuous development. “All measures have been and continue to be focused on our customers, whom we want to offer a vehicle that is perfectly tailored to their needs,” Katzer emphasises. “This year, we are taking the next step with the new MAN battery generation and further improving the already outstanding vehicle concept. This will have an enormously positive impact on issues such as TCO, safety and sustainability.”

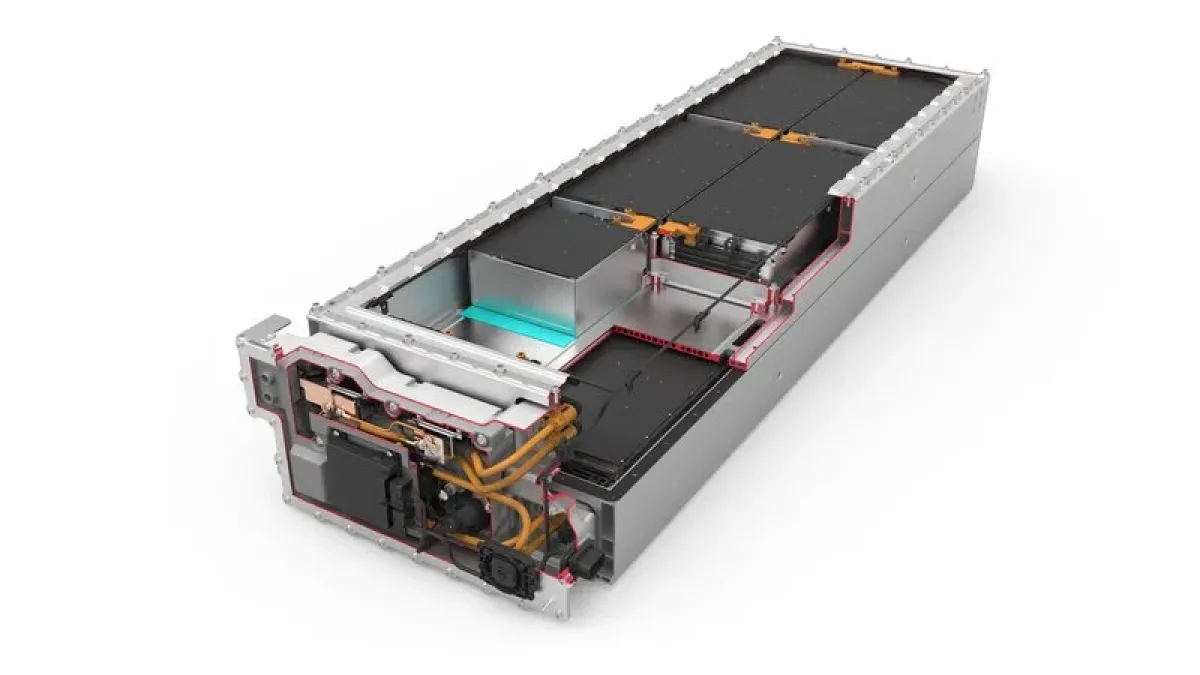

The new batteries, which will be produced in large series at the MAN battery plant in Nuremberg, are more efficient, lighter and have increased energy density and improved discharge depth. This means that fewer battery packs are needed despite the same or even increased range, which has a positive effect on passenger capacity and thus on total operating costs. Thanks to the modular battery approach, customers can continue to tailor the battery capacity of the Lion's City 12 E and Lion's City 18 E to their individual requirements. At the start of the model year, the 12-metre solo bus will be available with four or five battery packs with a capacity of 356 or 445 kWh, and the articulated bus with six or seven battery packs with a capacity of 534 or 623 kWh. In future, a configuration with six packs (Lion’s City 12 E) and eight packs (Lion’s City 18 E) will expand the range. This choice allows

customers to tailor the eBuses perfectly to their requirements in terms of passenger capacity and range. The Lion’s City 10 E is delivered with four battery packs (356 kWh).

“To ensure that every operator gets the ideal eBus for their needs, we are continuing to offer two battery usage strategies for the Lion's City E. New from model year 2025 is the option of combining both usage strategies individually with the desired battery capacity. This offers customers maximum flexibility,” explains Heinz Kiess, Head of Product Marketing Bus. The ‘Maximum Range’ strategy is available for particularly high daily ranges of up to 380 kilometres. Thanks to an extended discharge depth of up to 90 percent, enough energy can be extracted per charge for longer distances. The ‘Reliable Range’ battery usage strategy is suitable for operators who require a consistently reliable range throughout the entire service life of their fully electric buses. Continuously adapted to the ageing of the battery, the discharge depth increases steadily over the service life, starting at 65 percent. This guarantees a consistently high range of up to 270 kilometres under favourable conditions throughout the entire service life. “This makes the Lion's City E ideally suited for all routes and all urban transport scenarios,” says Kiess.

More efficient, safer and more sustainable However, the new batteries are not only more efficient, but also safer. MAN uses NMC cell chemistry (nickel-manganese-cobalt) in its batteries, which has been specially adapted for use in commercial vehicles. The battery management system (BMS) continuously monitors the condition of the cells during operation. If, for example, an unforeseen event occurs, it takes internal measures to ensure a safe condition. In the event of an accident, the BMS immediately disconnects the battery from the rest of the vehicle (highvoltage emergency shutdown). It also uses an intelligent heating and cooling system to keep the battery cells within an optimum temperature range at all times.

Issues such as safety, energy content taking into account weight and space availability, robustness and costs have been and remain at the heart of MAN's battery technology development. However, sustainability, reuse and recycling also play a central role. The initial aim is to extend the life of the batteries and, when this is no longer possible, to recycle the raw materials they contain. For MAN, this begins with the battery's first life in the vehicle, where the focus is on a particularly long service life. “Thanks to new findings and continuous development, it is now possible for customers to cover a total of one million kilometres with our batteries over their service life of up to 14 years,” says Kiess. This is made possible by the high cycle stability of the optimised MAN cell technology and intelligent battery management, which protects the batteries from unnecessary stress and thus prevents premature ageing. Sustainability is also ensured by the highly efficient and resource-saving production at the MAN plant in Nuremberg. Thanks to the expansion of a closed-loop recycling system and established recycling processes, up to 96 percent of the batteries can be recycled. This means that future legal requirements are already being exceeded today.

All key components in the eBus are ‘Made by MAN’ “By using our own MAN batteries from 2025 onwards, all key components of our eBuses will now come from within the Group,” explains Robert Katzer. The electronics platform introduced in the 2024 model year is based on the proven technology kit used in MAN's truck series. The electric motor and transmission come from the TRATON GROUP. “This enables us to guarantee the highest quality and continuous further development of the components – an important basis for achieving our goal: by 2030, we want to deliver up to 90 percent of our buses in Europe with battery drive.” MAN is thus following its own standards, but also meeting customer demand for sustainable mobility: around 70 percent of tenders issued by European cities now require electric buses. “This is a great development. To drive it forward, we will continue to develop our MAN Lion’s City E and provide companies with the best possible support in their transition to eMobility,” says Kiess.